Sustainable energy systems

Carbon dioxide removal (CDR) processes

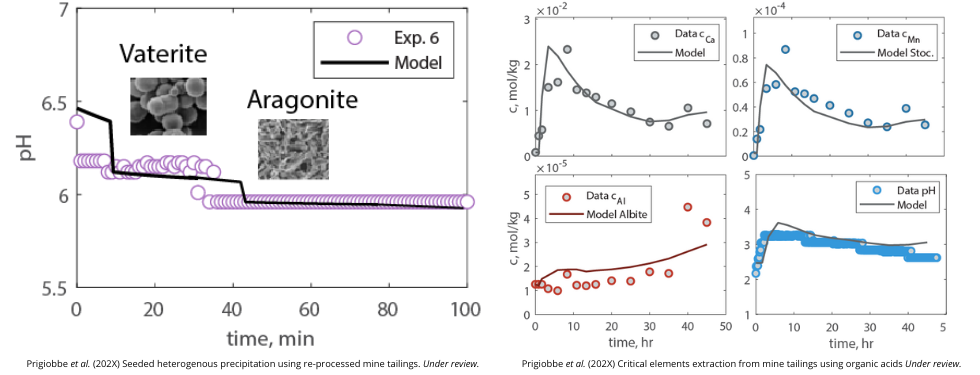

We work on CDR using the carbon dioxide (CO2) mineralization process. CO2 is reacted in slurry with metal oxides from silicates or waste (e.g., mine tailing and brines) to produce carbonate minerals. To off-set the cost of removal, we are integrating it with the recovery of critical minerals (CMs) from materials also rich in metals (e.g., Ca and Mg) that can react with CO2 making mining a net-zero carbon operation. We perform experiments in the lab using online-controlled systems and we describe the measurements with mathematical models coupled with geochemistry.

Recovery of critical minerals (CMs) from mine tailing and brines

We work on the mining of critical minerals (CMs) from waste such as mine tailings and brines. We focus on the dissolution and membrane separation processes for the extraction and recovery of elements such as Cu, Al, Mn, and Ni.

To off-set the carbon dioxide (CO2) emissions of the operation we are integrating the mining with the CO2 mineralization where CO2 is reacted in slurry with the extracted and separated alkaline earth elements to form carbonate minerals such as CaCO3 or MgCO3 that can be reused in construction. We perform experiments in the lab using online-controlled systems and we describe the measurements with mathematical models coupled with geochemistry.

Professors coordinating and developing projects related to this research pathway: Valentina Prigiobbe